What is sputtering?

Typical film forming method of PVD (Physical Vapor Deposition).

A method in which high-energy argon ions are bombarded to targets of various materials such as precious metals in a high vacuum, and metal atoms which are struck by argon ions are deposited.

We offer thin film by various sputtering as one method of consignment film forming.

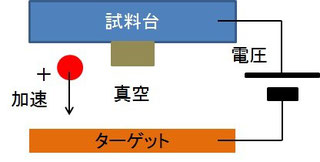

Principle (DC sputtering)

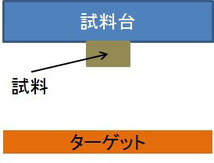

- Set the sample (substrate) to which the film is to be applied and the raw material of the film (target) in the equipment.

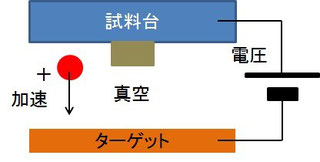

- Vacuum the inside of the equipment, apply a voltage between the substrate and the target.

- Argon gas is put into equipment and ionized by making plasma.

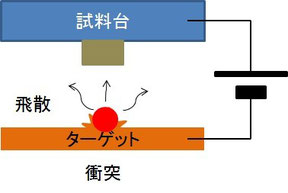

- High-speed accelerated argon ions collide with the target.

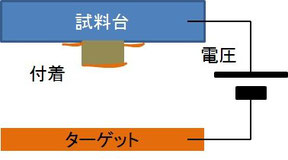

- The particles of the target struck by the collided ions adhere to the substrate and become a film.

About various sputters

DC sputtering

<Advantages>

- The energy of the particles as the raw material of the film is large and the adhesion to the substrate is strong.

- Film can be formed without changing the composition ratio of raw materials of alloy and compound.

- Film forming of high melting point material which is difficult by vacuum deposition.

- Deposition of reactive gas enables film formation of oxide and nitride.

- By applying electric power to the substrate side, it is possible to clean the substrate (reverse sputtering).

- The deposition rate is faster than other sputtering.

<Disadvantages>

- Ions will deposit on the surface of the insulator target and discharge will not occur.

- In order to get electric discharge, the degree of vacuum in the equipment is relatively low, and it is susceptible to the influence of gas.

- The substrate is damaged by the plasma.

- Anomalous discharge is likely to occur.

RF sputtering

<Advantages>

- The energy of the particles as the raw material of the film is large and the adhesion to the substrate is strong.

- Film can be formed without changing the composition ratio of raw materials of alloy and compound.

- Film forming of high melting point material which is difficult by vacuum evaporation.

- Introduction of reactive gas enables film forming of oxide and nitride.

- By applying electric power to the substrate side, it is possible to clean the substrate (reverse sputtering).

- Insulation film can be made.

<Disadvantages>

-

Film forming rate is slower than DC sputtering.

- Since the power supply and the matching box are necessary, the equipment becomes expensive.

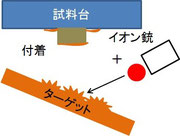

Ion beam sputtering

Unlike the above two methods, a film forming method without discharge.

Ions which are released from the ion gun bombard the target, and particles are ejected.

<Advantages>

- It is not necessary to make plasma by discharge, so film forming in a high vacuum environment is possible. Consequently, impurities are less contaminated.

- It is possible to set conditions that are not affected by the conductivity of the target.

- Ultra thin film (10nm or less) can be formed.

<Disadvantages>

- Film deposition rate is slower than DC and RF sputtering.

- Since the mechanism becomes complicated, the equipment becomes expensive.

Application field of sputter deposition

・ CD/DVD ・ Semiconductor ・ Magnetic head

・ Liquid crystal related (transparent conductive film)

・ LED ・ Photocatalyst ・ Battery

・ Various MEMS